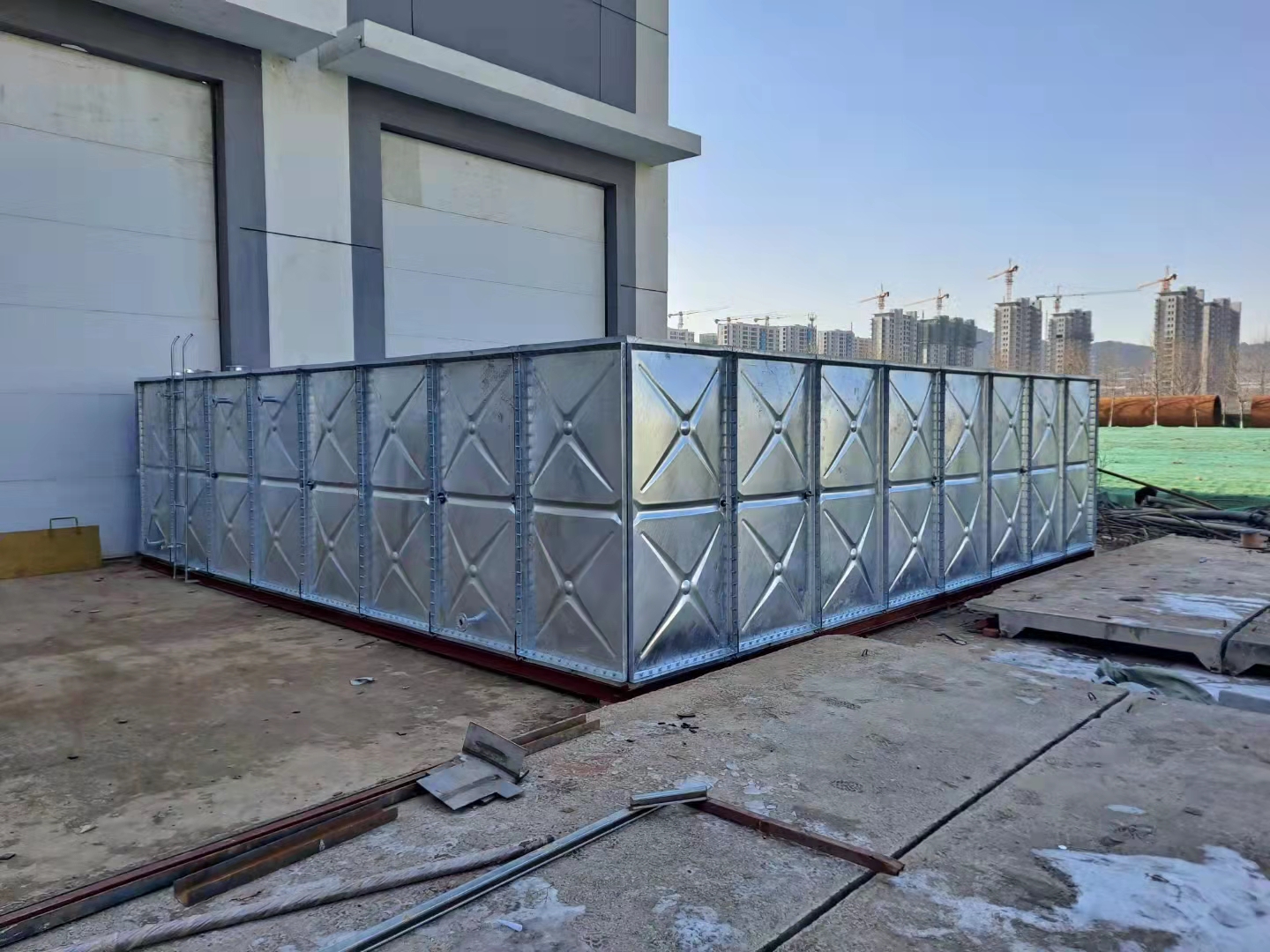

Congratulations to the customer for the successful installation of the hot-dip galvanized water tank!

We offers a full design, fabrication, protective treatment, shipment & erection service for tanks, towers and ancillary items. Design work is in accordance with 12S101 and GB50017-2017, GB50009-2019 , including the incorporation of any specified seismic, wind loading to be accommodated for the towers.

Qualified engineers can be provided to supervise erection or to fully manage construction sites.

Shandong NATE can supply their own teams of trained subcontractors to carry out all forms of erection, modification or refurbishment. The labour force is fully conversant with the working and safety procedures relating to large construction projects, time constraints imposed by plant shutdowns and the requirments of particular industries.Shandong NATE offer their services through China and worldwide.

THE CONCEPT

Shandong NATE hot dip galvanized steel water tanks are formed using massproduced tank plates and accessories, and stays bolted together on site, to given an infinaite range of sizes and capacities.

Though generally square or rectangular in construction, tanks can be provied in a variety of forms to suit particular site conditions or project requirements. The most common deviations are “I” or “T” shaped tanks (plan or elevation) and tanks “noteched” to avoid obstructions.

Through a variety of flanging arrangements Shandong NATE tanks can be designed to be supported on concrete rafts or consolidated foundations (where headroom is restricted), on grillages at ground level or in plant rooms (providing access to the underside for inspection and maintenance) or elevated on steel or concrete towers.

The modular concept and bolted construction allows for high speed assembly utilising semiskilled labour. This provides obivious client advantages and cost benefits associated with reduced site duration’s when considered against traditional concrete or welded steel construction.

Although best known for the storage of water, a wide range of liquids can be stored in Shandong NATE steel water tanks and the sectional method is also well suited to the storage of solids in granular or flake form.

TANK PLATES

The standard tank plates are 1000mm o r 1200mm square, pressed from mild steel plates in one piece and embossed with “X” pressing. Thickness of panel ranges from 2.0mm to 6.0mm, determined by tank depth and contents.

COVERS

Covers are constructed from flanged tank plates and are designed to with loading imposed by maintenance personnel. Covers are fabricated from 3mm or 2mm thick steel plate, and suitable jointing materials ensure covers are dust or weatherproofed to suit their application.

DIVISIONS

To enable maintenance of the tank without interruption of the water supply, tanks can be fitted with divisions. Divisions are constructed from standard tank plates and are designed to operate with either compartment empty.

TIE BAR

All internal fittings are fabricated from steel and carefully designed to ensure the strength and rigidity of each tank size. Where special applications make the use of internal staying impossible, I steel and U- channel steel can be provided externally.

Steel water tank reinforced with steel bar as horizontal tie bar at the cross joint of side plates, reinforced with steel plate as inside tie bar plate at the cross joint of side plates, reinforced with steel plate as outside tie bar plate at the cross joint of side plates.

JOINTING MATERIALS

Sealing rubber strips are used to seal between the water tank plates and the water tank plates to ensure that the water tank will not leak.

Post time: Jun-28-2022